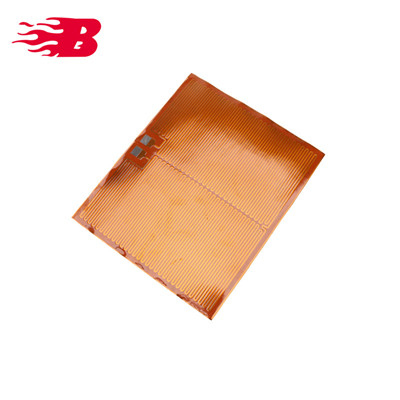

PI electric heating film of polyimide film is made of polyimide film as outer insulator, metal foil and metal wire as inner conducting heat generator, which is heated at high temperature and high pressure. Polyimide electrothermal film is widely used in the field of electric heating because of its excellent insulation strength, electrical resistance, heat transfer efficiency and resistance stability.

1. Surface heating, high thermal efficiency, energy saving and power saving

Polyimide film electric heater is a kind of surface heating material, which forms the maximum heat conduction surface with the heated body and has small heat transfer resistance. The heat can be transmitted to the heated body quickly when the electric heating is on, and because of the good thermal conductivity of this heating method, the temperature of the electric heating film itself is not too high, there is no redness and blazing phenomenon, and the radiation heat loss is very small. Therefore, the thermal efficiency of the electric heating appliance made of the electric heating film is quite high, generally around 90%. However, the traditional point heat source has a small heat dissipation area, and it is conducted indirectly with the heated body by other objects. In the process of electric heat conversion, the heat energy generated by electric energy can not be transmitted to the heated body quickly, which causes the heat on the electric heating element to be too concentrated, the element itself quickly becomes hot, a large part of the electric energy becomes light energy and dissipates, resulting in low electric heat conversion efficiency.

The polyimide film electric heater can be used for heating the position that needs to be heated. You only need to place them on the surface of the part to be heated. The thin structure can provide close thermal coupling between the electric heating element and the radiator. In areas with high heat loss, you can even specify a higher power density configuration heating mode.

In the contrast experiment, with the same power and the same type of container, boiling the same amount of water, the electric heating film electric pot saves 50% of the electricity compared with the electric furnace, the electric heating film enamel pot saves 10% - 20% of the electricity compared with the electric heating tube pot, the electric heating film metal pot saves 20% - 40% of the electricity compared with the general electric heating tube pot, and the electric heating film electric heater has obvious energy-saving effect.

2. Fast preheating, long service life and not easy to damage

For a large surface area, the heat transfer effect of the foil element of the polyimide film electric heater is higher than that of the wire wound electric heater. Therefore, the thermal difference between the resistance element and the radiator of the polyimide electric heating film is not very obvious, and the temperature of the electric heating film remains low. When the power of the electric heating film is twice that of the wound heating plate, it can still operate safely. The insulation life can be up to ten times of that of the wound type electric heater. General electric heat source is always used in the hot state, so it is easy to produce oxidation, resulting in open circuit. However, due to the large contact surface and fast heat conduction, the temperature of the electric heating film is relatively low, which improves the oxidation problem of the electric heating film material in the state of electric heating and prolongs its service life.

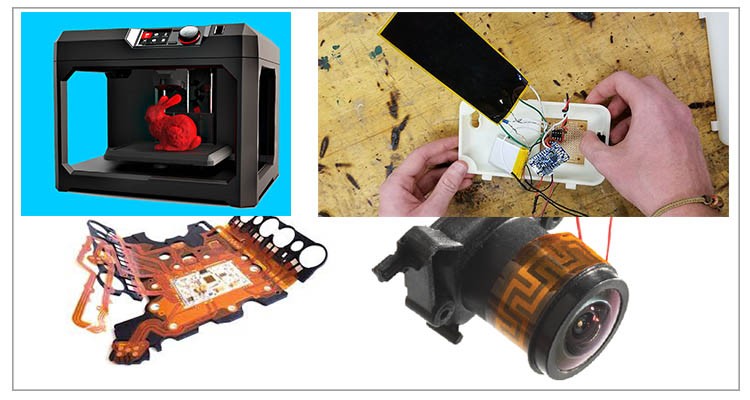

3. Strong shape selectivity and wide application range

The electrothermal film can be made into film shape, linear shape, cut different length and size according to the needs, and fixed on the surface of the heated object by means of covering, pasting, winding, etc., and the vessels or working surfaces with various complex shapes can be coated. This characteristic of the electric heating film makes the application range of the electric heating film more extensive than that of the traditional electric heating elements.

4. No open fire, safe and reliable

There is no open fire in the process of electrothermal conversion. When the electric heating film heater is heated to 100 ℃ boiling water, the electric heating film will not burn paper, cotton, matches, and contact with them will not ignite. Therefore, the electrothermal film is very suitable for some special places which need to be heated and insulated, but no open fire is allowed.

5. Save space and weight

The weight of polyimide metal electrothermal film is usually only (0.04q / cm2), and the measured thickness in the element is only (0.12mm). For areas with limited space, such as defense electronics, aerospace equipment, portable medical equipment, high-density electronic equipment, polyimide film electric heater can meet your requirements.

6. Corrosion and radiation resistance

Resistant to most chemicals, such as acids and solvents. It can resist 106 rad radiation.

7. Customized device

Custom options provide the perfect solution package, significantly reducing assembly time and increasing productivity. Customized configuration can provide balanced heating output performance to improve processing capacity and productivity.