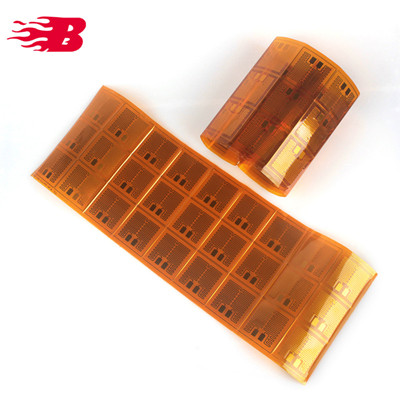

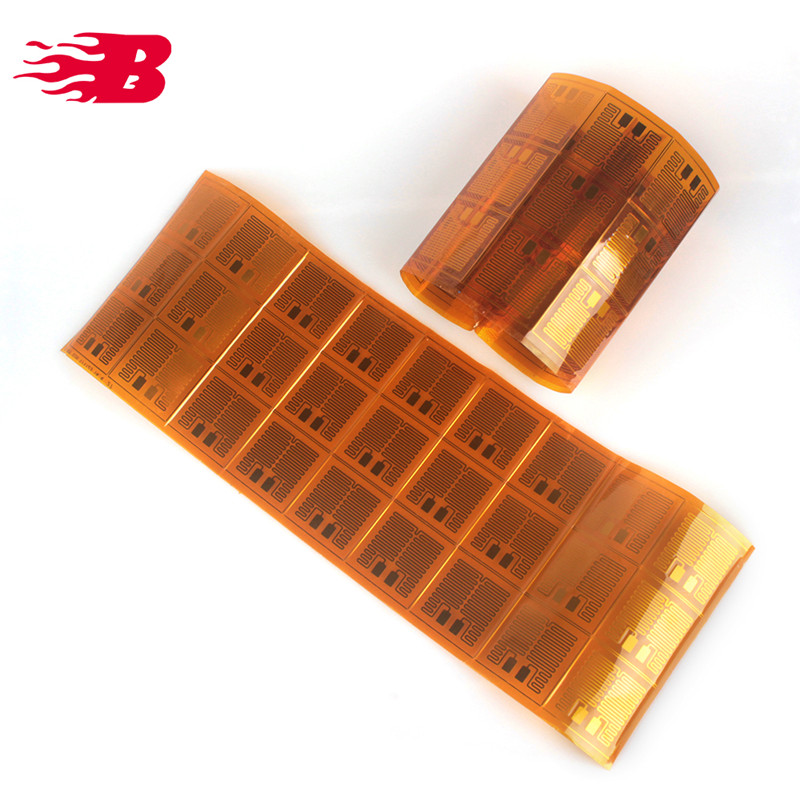

polyimide film heater

Polyimide thermo foil heater are available in a variety of shapes, sizes, and wattages. Polyimide Film offers a high degree of resistance to chemicals, and has excellent outgasing properties in high vacuum environments.

Polyimide is an organic polymer with very high dielectric capability and thin profile, while providing superior resistance to most solvents, oils, and radiation.

Flexible heating film is a clear amber colored polyimide film. The process for making flexible heating film is similar to that of Etched Foil Silicone heaters. It is a high-temperature flexible heating element with excellent dielectric properties capable of operating environments between -185 degree celsius to 200 degree Celsius

Customize 12V,24V,36V 3D printer flexible heating film with CE certification,and we usually say it is polyimide heaters.

This is is very thin,the thickness is about 0.3mm,it is very light,so it is widely used on 3D printer.the normal size for 3D printer are follow,

1,200x200mm,12v,200w

2,260x290mm,12v,145w

3,200x250mm,12v,90w and so on. any size,any shape can be customize. please contact with us

Advantages of polyimide electric film haeater

1.Planar heating, high thermal efficiency, energy saving

Polyimide film electric heater is planar heating material, with the heated body formed to maximize the thermal conductivity, small heat transfer resistance.Ohmic heating heat can be quickly transferred to the heated body, and because of this heating good thermal conductivity, so the heating temperature is not too high,not red, glowing, radiant heat loss is very small,hence the electric membrane made of electric appliances, thermal efficiency is very high, generally around 90%. As the traditional point of heat dissipation area is small, and other objects to be heated depends on indirect conduction, the electrothermal conversion process, the heat generated by power transmitted can be heated quickly, resulting in the heat of the heating element is too concentrated, the element itself becomes hot quickly, a large part of energy into a light energy loss, resulting in electric conversion efficiency is low.

Polyimide film type electric heater can be heated for the location of the heating. You only need to put them in need to heating the surface of the parts. The light-weight structures in the electric leaf provide close thermal coupling between components and radiator. In the area of heat loss is bigger, you can even specify the configuration using higher power density heating mode.

2.Preheat fast, long life, easy to damage

For larger surface area of the polyimide film-type electric heater of the heat transfer element plates foil effect higher than the winding type heater. Therefore polyimide electrothermal film is formed between the resistive element and heat sink thermal difference is not very obvious, electric film remains relatively low temperature state. General electric heat source is always used under hot condition, so it is prone to oxidation, joint caused by open circuit. The electric film work due to a large contact surface, fast heat conduction, so its temperature is low, which improves the ohmic heating electric film material in the oxidation state of their own problems, prolongthe service life.

3.Overall optional strong, wide application

Electric membrane can be made in film, linear, can according to the need of the interception of different length and size, with wrap, paste and winding is fixed in the heated surface, the complex shape of the vessel or the work surface can be coated. The characteristics of electric heating film application range of the electrothermal film heating element is much wider than the traditional.

4.No open flame, safety and reliability

Electric film in electric conversion process does not produce fire. When the electric film heater is heated to 100 °C boiling state, the electric film does not burn paper, cotton, matches, it will not ignite in contact with. Therefore, it is suitable for some electric film heating insulation needs, but does not allow application of special places exposed to open flames.

5. Save space,reduce weight

Polyimide metal electric heating film weight usually only (0.04 q/cm2), measuring the thickness of element only (0.12mm). For areas with limited space, such as defense electronics, aerospace equipment, portable medical equipment, high-density electronic devices, polyimide film electric heater can meet your requirement.

6.Anti-corrosion, anti-radiation

Resistant to most chemicals, such as acid and solvent corrosion. Resistant to 106 rads of radiation.

7.Custom Device

Custom options can provide the perfect complete solution, significantly reducing assembly time and improve productivity. Custom configuration provides a balanced heating output performance, in order to improve the processing capacity and productivity.